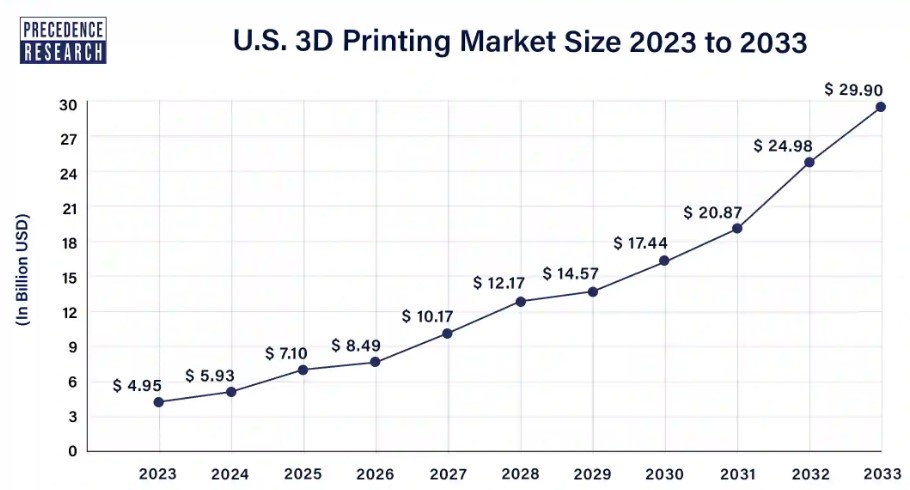

Economic Impact of 3D Printing Adoption

1. Reduced Manufacturing Costs

One of the most significant economic implications of 3D printing is its potential to reduce manufacturing costs. Traditional manufacturing methods rely on expensive tooling, molds, and mass production techniques, which incur significant setup costs. In contrast, 3D printing eliminates the need for such setups by allowing parts to be created layer by layer directly from digital designs.

The ability to produce small, customized batches of goods without expensive molds will lower the entry barriers for manufacturers and make small-scale, local production more economically feasible. Additionally, reduced waste in production processes and lower transportation costs for producing goods closer to end consumers further contribute to lowering overall costs.

2. Supply Chain Disruption and Transformation

One of the biggest areas impacted by widespread 3D printing adoption is the global supply chain. 3D printing allows for localized, on-demand production, reducing the need for large-scale, centralized manufacturing facilities and the transportation of goods over long distances. This reduces dependency on global supply chains and minimizes shipping costs and delays, which are critical for industries like automotive, aerospace, and healthcare.

Additionally, factories will no longer need to store large inventories of parts and products since replacement parts and customized goods can be printed on demand. This shift will lead to leaner, more agile supply chains and reduce the need for warehousing and other logistical operations.

While 3D printing can bring flexibility to supply chains, it could also impact the traditional logistics industry. For example, the demand for logistics workers may diminish as the need to transport and store massive inventories declines. Instead, the focus will shift to trained workers skilled in operating 3D printing systems and managing decentralized manufacturing processes.

3. Impact on Employment and Job Displacement

The widespread adoption of 3D printing will have profound implications for the workforce. On one hand, new opportunities will emerge in sectors related to 3D printing technologies, such as design, engineering, software development, and 3D printer operation. Demand for workers with specialized skills in additive manufacturing, digital design, and logistics management will rise as companies shift to this new production model.

On the other hand, traditional manufacturing jobs, particularly those related to mass production, machining, and inventory management, could see a decline. As 3D printing reduces the need for large-scale manufacturing facilities and inventories, many low-skill, labor-intensive jobs could be displaced.

The transition may also affect logistics and shipping jobs, as fewer products will need to be transported over long distances. However, while job displacement is a concern, the new employment opportunities emerging from 3D printing will require investments in education and training to equip workers with the necessary skills to thrive in this evolving landscape.

4. Increased Customization and Innovation

3D printing’s ability to produce highly customized products without significant additional costs opens new doors for businesses to meet consumer demands in unique ways. Mass customization—the ability to produce individualized goods at scale—becomes possible. For example, companies can create personalized medical devices, clothing, and consumer goods that cater specifically to individual preferences and needs.

This increased customization and flexibility will encourage innovation across industries, with companies able to rapidly prototype and test new products without the delays and costs associated with traditional manufacturing. The rise of 3D printing could lead to a new era of creativity and experimentation, where manufacturers can pivot quickly to meet changing market demands.

5. Energy Efficiency and Sustainability

The economic impact of 3D printing goes beyond immediate cost savings. One of the most promising aspects of 3D printing is its energy efficiency compared to traditional manufacturing methods. Conventional manufacturing often involves subtractive processes (removing material from a larger piece), which can be wasteful. In contrast, 3D printing uses additive processes, building objects layer by layer and using only the necessary material.

Additionally, 3D printing allows companies to produce goods closer to where they are needed, reducing the carbon footprint associated with transportation and shipping. This energy efficiency and reduction in waste contribute to more sustainable production methods, aligning with global efforts to reduce the environmental impact of manufacturing.

6. Decentralized Production and Local Economies

Widespread 3D printing adoption could lead to the decentralization of production, with smaller manufacturing facilities scattered across regions instead of centralized, large-scale plants. This decentralization has the potential to stimulate local economies, reduce reliance on global supply chains, and create localized jobs in production, design, and logistics.

Localizing production could also strengthen regional economies, giving rise to opportunities for small businesses and entrepreneurs who can capitalize on the flexibility that 3D printing provides. The technology allows for rapid iteration and production, enabling smaller players to compete with larger corporations in terms of speed, innovation, and customization.

Challenges of Widespread 3D Printing Adoption

1. Cost of Technology and Materials

While 3D printing technology is rapidly evolving, the initial investment in advanced 3D printers, materials, and the required software can be prohibitive for small businesses. Additionally, some high-performance 3D printing materials, such as metals and specialized polymers, can be expensive, which limits the technology’s accessibility for some sectors.

As more affordable 3D printing solutions and materials become available, this challenge will likely diminish, but for now, it remains a barrier to widespread adoption.

2. Regulatory and Intellectual Property Issues

As 3D printing becomes more prevalent, regulatory and intellectual property concerns will need to be addressed. The ability to produce nearly any item from a digital file raises concerns about copyright infringement, patent violations, and counterfeiting. Governments and industries will need to establish clear regulations to protect intellectual property rights in the age of on-demand, decentralized production.

Additionally, in industries like healthcare, aerospace, and automotive, there will need to be stringent regulations and certification standards for 3D-printed parts to ensure safety, durability, and reliability.

3. Skill Gaps and Workforce Training

As 3D printing adoption increases, a significant challenge will be the skill gap in the workforce. Workers will need to be trained in digital design, 3D printing operation, material science, and process optimization to manage these new manufacturing processes. Investing in education and vocational training programs will be essential to ensure that workers can transition to the new roles required by 3D printing technology.