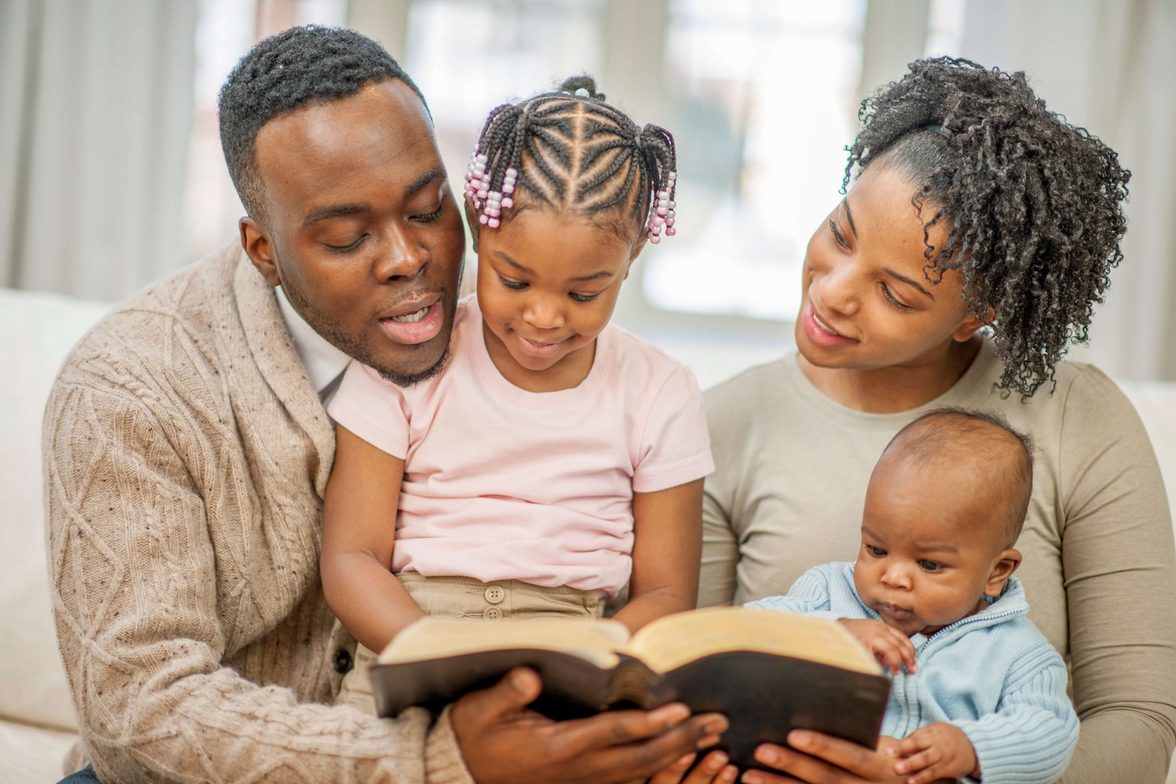

Planning Pregnancy Together: Creating a Family Altar, Reading Scriptures, and Setting Intentions

Pregnancy doesn’t begin with a positive test—it begins with a shared intention. In the spiritual view of conception, especially within Vedic and holistic traditions, planning a