The Environmental Benefits of 3D Printing

Before diving into the environmental risks, it is important to recognize the positive impacts of 3D printing:

1. Reduced Waste

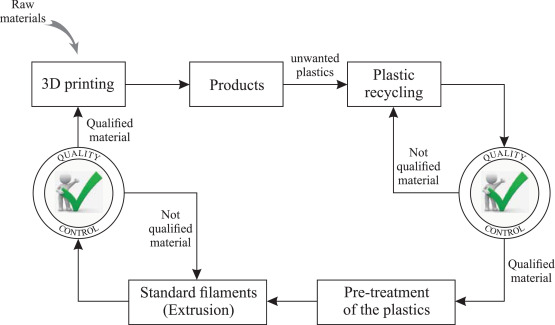

Traditional manufacturing methods, particularly subtractive manufacturing (where materials are cut away from a larger block), often result in large amounts of waste. In contrast, additive manufacturing (the process used in 3D printing) creates objects layer by layer, leading to minimal material waste. This makes 3D printing a more sustainable option in industries where precise, complex parts are needed.

2. Localized and On-Demand Production

3D printing can reduce the need for global supply chains by enabling localized production. As products can be printed closer to their final destination, there is less need for long-distance transportation, which, in turn, reduces carbon emissions. The ability to print parts on demand also minimizes the need for warehousing and excess inventory, further reducing waste and energy consumption.

3. Energy Efficiency

When compared to traditional manufacturing methods that often involve high temperatures, extensive machining, and energy-intensive processes, 3D printing can offer a more energy-efficient alternative. New technologies, such as direct energy deposition (DED) and powder bed fusion (PBF), are being developed with improved energy efficiencies, which will reduce the overall carbon footprint of production processes.

While these benefits are promising, it’s crucial to address the environmental risks that may accompany the future expansion of 3D printing, particularly in metal 3D printing.

Potential Environmental Impacts of 3D Printing Materials

As 3D printing technology advances and its applications expand, the use of various materials, including polymers, metals, and composites, will continue to grow. However, the environmental impact of these materials should not be overlooked.

1. Non-Recyclable Metal Powders

One of the most pressing concerns is the use of metal powders in 3D printing. While metal 3D printers offer the potential for more efficient and localized production of high-performance parts, many of the metal powders used in these processes are non-recyclable.

For example, titanium, aluminum, steel, and nickel-based alloys are common in industries such as aerospace and automotive, where strength and durability are essential. However, once these powders are used in the printing process, they may not be reusable, leading to material waste. This presents a challenge in terms of both sustainability and resource depletion, particularly given the finite supply of certain metals.

2. Toxicity and Health Risks

In addition to being non-recyclable, some metal powders can be toxic if not handled correctly. The fine particles used in 3D printing can pose health risks to workers, including respiratory issues. Without proper safety measures, exposure to these powders can lead to occupational hazards.

Furthermore, if these materials are not disposed of correctly, they can have a negative impact on the environment, contaminating soil and water sources. This highlights the importance of developing safe handling practices and recycling initiatives for 3D printing materials.

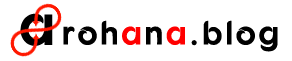

3. Plastic and Polymer Waste

While metal 3D printing is growing in popularity, plastic and polymer-based 3D printing still dominate the consumer market. The use of non-biodegradable plastics, such as PLA, ABS, and PETG, can contribute to plastic pollution if not properly recycled. While some filaments, like PLA, are marketed as biodegradable, the reality is that they often require industrial composting facilities to break down properly, which may not be widely available.

As 3D printing becomes more widespread, the potential for increased plastic waste is a significant environmental concern, particularly if hobbyists and small businesses are not equipped with the knowledge or tools to dispose of these materials responsibly.

4. Energy Consumption and Carbon Footprint

While 3D printing can offer energy efficiencies in some cases, it’s important to note that certain metal 3D printing processes can be energy-intensive. Technologies like laser powder bed fusion (LPBF) require significant amounts of energy to heat materials to the necessary temperatures for melting and fusing metal particles.

Additionally, the production of metal powders themselves can be energy-intensive, contributing to carbon emissions before the printing process even begins. As 3D printing becomes more integrated into industrial manufacturing, the total energy consumption and carbon footprint associated with it could increase unless renewable energy sources are prioritized.