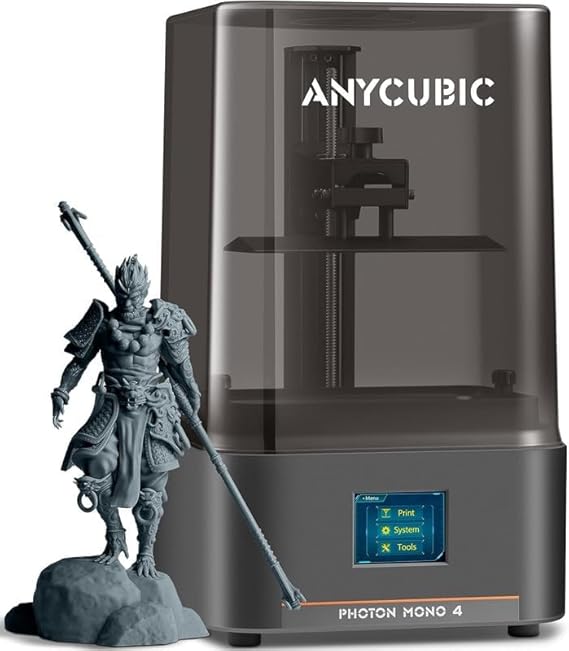

The Impact of 3D Printing on Consumer Goods Production

1. Customization

One of the most significant advantages of 3D printing is its ability to create custom products tailored to individual consumer needs. Imagine a scenario where consumers can scan their feet to design custom-fit shoes, ensuring maximum comfort and support. This level of personalization extends beyond footwear to a wide range of products, from tailored clothing to custom medical devices, allowing businesses to cater to the unique preferences and requirements of their customers.

2. Supply Chain Resilience

3D printing can enhance supply chain resilience by minimizing reliance on physical inventory. Traditional manufacturing often requires extensive warehousing and transportation of goods, which can be vulnerable to disruptions. With 3D printing, businesses can produce items on-demand, significantly reducing the need for large inventories. This capability allows companies to respond swiftly to changes in consumer demand or supply chain disruptions, fostering a more agile and robust production system.

3. Energy Efficiency

In an era increasingly focused on sustainability, energy efficiency is a critical concern. 3D printing is generally more energy-efficient than conventional manufacturing methods. By using only the materials necessary to create a product, this technology reduces waste and can lower the carbon footprint associated with production. As consumers and businesses alike prioritize eco-friendly practices, 3D printing offers a compelling solution to mitigate environmental impact.

4. Decentralized Production

3D printing enables decentralized production, allowing businesses to move manufacturing closer to local markets. This shift not only reduces transportation costs and emissions but also allows for quicker response times to consumer needs. For example, local production facilities can quickly adapt to trends or preferences within their communities, fostering a more tailored consumer experience.

5. Innovation

The flexibility of 3D printing encourages innovation by allowing companies to experiment with new designs without the prohibitive costs associated with traditional manufacturing methods. Designers can create prototypes rapidly, test different materials, and bring innovative products to market faster. This creative freedom can lead to groundbreaking advancements in consumer goods across various industries.

6. Personalized Nutrition

3D printing can revolutionize the food industry by enabling dietitians and chefs to design meals tailored to individual nutritional needs. With the ability to create custom food shapes, flavors, and textures, 3D-printed meals can enhance dining experiences while ensuring that nutritional requirements are met. This personalization can play a vital role in health management and dietary preferences.

7. Gastronomy

In the culinary world, 3D printing offers chefs unique opportunities to create visually stunning dishes that challenge traditional cooking methods. By experimenting with shapes, textures, and combinations of ingredients, chefs can craft innovative dining experiences that engage and delight consumers. This fusion of technology and gastronomy opens new avenues for culinary creativity.

Importance of 3D Printing in Consumer Goods Production

The importance of 3D printing in consumer goods production lies in its ability to meet the evolving demands of consumers and the market. As consumers increasingly seek personalized, sustainable, and innovative products, 3D printing stands out as a technology that can deliver on these expectations. Furthermore, it enhances supply chain efficiency, reduces environmental impact, and fosters a culture of innovation, ultimately contributing to economic growth and competitiveness.

Challenges Facing 3D Printing in Consumer Goods Production

While the potential benefits of 3D printing are substantial, several challenges need to be addressed for its widespread adoption in consumer goods production:

1. Job Displacement

One of the primary concerns surrounding the adoption of 3D printing is the potential for job displacement. As production processes become more automated and localized, traditional manufacturing jobs may be at risk. It is essential for policymakers and businesses to consider strategies for workforce retraining and upskilling to mitigate this impact.

2. Workers’ Rights

The shift towards decentralized production raises questions about workers’ rights and labor conditions. As companies move manufacturing closer to consumers, there must be a focus on ensuring fair labor practices and ethical treatment of workers, especially in regions where labor laws may be less stringent.

3. Quality Control

Ensuring consistent quality across 3D-printed products can be challenging. Variability in materials, processes, and equipment can lead to inconsistencies in product performance and safety. Establishing robust quality control standards and regulations will be critical to maintaining consumer trust and safety.

4. Material Limitations

While 3D printing materials are advancing, not all materials are suitable for every application. The development of a broader range of sustainable and high-performance materials is necessary to unlock the full potential of 3D printing in consumer goods production.

5. Intellectual Property Issues

The ease with which 3D printing can replicate designs raises concerns about intellectual property rights. Companies must navigate complex legal landscapes to protect their innovations while fostering an environment of creativity and collaboration.