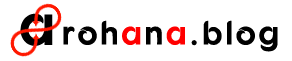

The Role of 3D Printing in Personalized Medicine

3D printing, also known as additive manufacturing, allows for the precise layering of materials to create complex structures. In the realm of personalized medicine, this technology offers significant benefits, including the ability to produce tailored medication formulations that meet specific patient needs. Here’s how it plays a crucial role:

1. Customized Dosage Forms

3D printing enables the creation of personalized dosage forms, such as tablets and capsules, that can be tailored to an individual’s specific dosage requirements. This flexibility allows for the adjustment of drug release profiles, shapes, and sizes, making it possible to enhance the therapeutic efficacy of medications.

2. On-Demand Production

The ability to manufacture medications on-demand means that pharmacies can respond swiftly to changing patient needs. This approach reduces the reliance on large-scale manufacturing processes, which often result in excess inventory and wastage. Instead, pharmacists can produce small batches of medications tailored to individual prescriptions, ensuring freshness and potency.

3. Complex Drug Combinations

3D printing allows for the combination of multiple medications into a single dosage form. This is particularly beneficial for patients who require polypharmacy—taking several medications for various conditions—as it can simplify their medication regimens and improve adherence.

4. Enhanced Patient Engagement

By involving patients in the design of their medications, 3D printing can increase engagement in their treatment processes. Patients can have a say in the flavor, appearance, and even dosage forms, leading to improved satisfaction and compliance.

Impact of 3D Printing on Personalized Medicine

The integration of 3D printing into personalized medicine is likely to create several significant impacts:

1. Improved Patient Outcomes

Customized medications can lead to better therapeutic results, as they are tailored to individual pharmacokinetics and pharmacodynamics. This personalization minimizes the trial-and-error approach often associated with traditional prescriptions, leading to more effective treatments.

2. Increased Access to Medications

3D printing can bridge gaps in medication accessibility, particularly in remote areas where traditional pharmacies may not stock specific drugs. On-demand production allows local pharmacies to meet unique patient needs without the constraints of inventory management.

3. Cost Efficiency

Although the initial setup costs for 3D printing technology can be high, the long-term benefits may include reduced manufacturing and distribution costs. By minimizing waste and streamlining the supply chain, 3D printing can make personalized medicine more economically viable.

Advantages of 3D Printing in Personalized Medicine

- Tailored Treatments: The ability to customize medications to meet individual needs enhances efficacy and reduces adverse effects.

- Flexibility in Formulation: Pharmacists can quickly adapt formulations based on patient feedback or emerging health needs.

- Reduced Waste: On-demand production minimizes the surplus of medications that may expire before use.

- Simplified Medication Regimens: Combining multiple drugs into a single dose can improve adherence and reduce confusion for patients.