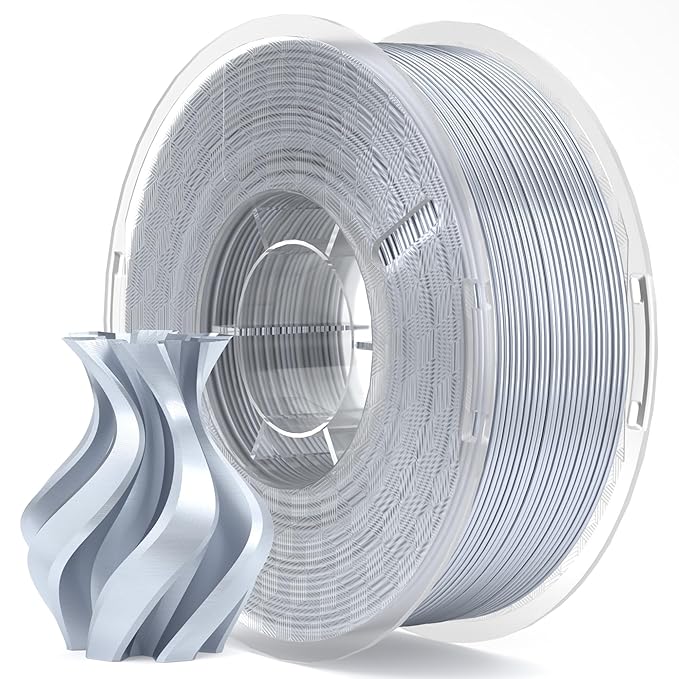

What is Resolution in 3D Printing?

In the context of 3D printing, resolution refers to the level of detail that a printer can achieve. It’s typically measured in microns (one-thousandth of a millimeter), and it determines how finely the printer can render the details of your design. Resolution affects the surface finish, accuracy, and overall quality of the printed object.

For FDM printers, resolution is influenced by several factors, including the diameter of the nozzle, the precision of the print head movements, and the layer height (the thickness of each individual layer of material that the printer lays down).

Typical Resolution Ranges for FDM Printers

FDM printers come in a wide variety of models, from desktop units used by hobbyists to industrial-grade machines utilized in professional settings. The resolution capabilities of these printers vary accordingly:

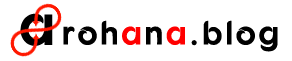

1. Desktop FDM Printers

- Resolution Range: 100 to 300 microns

- Use Cases: Prototyping, educational projects, hobbyist creations

Desktop FDM printers are the most common type of 3D printer available to consumers and small businesses. These printers are generally affordable and user-friendly, making them ideal for beginners and intermediate users. The typical resolution range for these machines is between 100 to 300 microns.

At the lower end of this range (300 microns), the printed objects may have visible layer lines and less detail, but they print faster. As you move to the finer resolutions (closer to 100 microns), the prints take longer, but the level of detail and surface smoothness improve significantly. This makes desktop FDM printers versatile enough for creating functional prototypes, simple models, and custom parts, although they may not be suitable for high-precision applications.

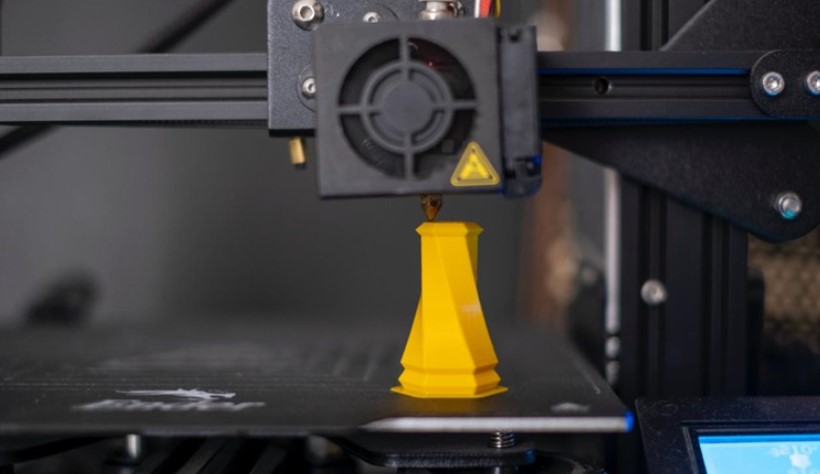

2. Industrial-Grade FDM Printers

- Resolution Range: 50 to 250 microns

- Use Cases: High-detail prototypes, functional parts, engineering applications

Industrial-grade FDM printers are designed for professional environments where higher precision and quality are required. These machines are typically larger, more robust, and offer finer control over the printing process. They can achieve resolutions ranging from 50 to 250 microns.

At 50 microns, the printed parts have a very smooth surface finish and can capture intricate details, making these printers suitable for creating detailed prototypes, custom jigs and fixtures, and even end-use parts in some cases. The ability to print at such fine resolutions allows manufacturers to produce parts with tight tolerances and consistent quality, which is essential in fields like aerospace, automotive, and medical device manufacturing.

Factors Influencing FDM Printer Resolution

While the resolution ranges mentioned provide a general guide, the actual resolution you can achieve with an FDM printer depends on several factors:

- Nozzle Size: Smaller nozzles can produce finer details, but they also slow down the printing process. Larger nozzles allow for faster prints but with less detail.

- Layer Height: A smaller layer height increases resolution and detail but also increases print time. A larger layer height decreases print time but at the cost of detail and surface smoothness.

- Printer Calibration and Settings: Proper calibration of the printer, including bed leveling and temperature settings, can significantly affect the final resolution of the print. Advanced printers may offer more precise control over these parameters.

- Material Choice: Different filament materials have different flow characteristics and cooling times, which can influence the resolution of the printed object. For example, PLA often produces smoother prints at finer resolutions compared to ABS.