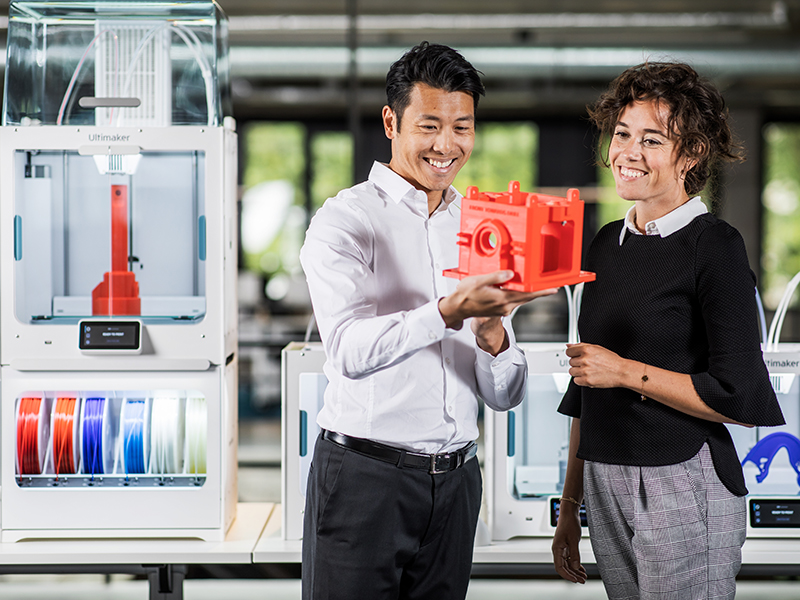

1. Versatility in Material Usage

One of the standout features of the Ultimaker S5 is its ability to print with a wide variety of materials, making it a versatile choice for professionals and industries. Unlike many 3D printers that are limited to a few materials, the S5 can print with everything from engineering polymers to carbon fiber composites, glass, recycled filaments, and even stainless steel.

This wide material compatibility allows users to choose the right material for their specific application, whether it’s creating tough functional parts with carbon fiber composites or producing smooth, durable components with advanced polymers. This flexibility enables engineers, designers, and manufacturers to use the S5 for different purposes, from prototypes to final products.

2. Easy-to-Use and Reliable Performance

One of the key selling points of the Ultimaker S5 is its “click and print” ease of use. Despite being a highly advanced machine, the S5 is designed to be accessible, even to those without extensive 3D printing experience. It comes equipped with preconfigured material profiles and an intuitive Ultimaker Cura software, making it simple to prepare, slice, and start a print.

The S5’s reliability is another feature that sets it apart. With its high level of automation and calibration, users can consistently produce high-quality prints without having to spend significant time troubleshooting or tweaking settings. The built-in sensors ensure proper bed leveling, and the dual extrusion system allows for seamless printing of complex geometries with support materials like PVA, which dissolves away post-print.

3. Large Build Volume

For those who need to print larger objects, the Ultimaker S5 offers a substantial build volume of 330 x 240 x 300 mm. This makes it ideal for printing large components or multiple smaller parts in one go. Unlike smaller printers, which may require breaking up large designs into smaller pieces, the S5 can handle large, continuous prints with ease.

This capability is particularly useful for industries like automotive, aerospace, and healthcare, where large, high-quality parts are often needed. Whether you’re working on architectural models, automotive prototypes, or industrial tooling, the S5’s build volume can accommodate a wide range of professional applications.

4. Dual Extrusion System

The dual extrusion system in the Ultimaker S5 is another standout feature, allowing for multi-material or multi-color printing. This capability is especially useful for complex prints that require both build material and support material. The S5 can automatically switch between materials like ABS and soluble PVA, allowing for the creation of intricate designs with internal structures or overhangs that would be difficult to print on a single-extruder machine.

The dual extrusion system also enables more aesthetic prints by combining different colors or materials in a single model. This feature is particularly beneficial for industries that require precision and complex geometries in their 3D-printed parts.

5. Advanced Engineering and Industrial Applications

The Ultimaker S5 is designed to meet the demands of real-world industrial applications. Whether you’re working with advanced engineering polymers or reinforced composites like glass and carbon fiber, the S5 provides the strength, durability, and precision needed for functional prototypes and end-use parts.

The printer is capable of printing materials that offer properties like high heat resistance, chemical resistance, and mechanical strength, making it ideal for applications in industries such as automotive, aerospace, and manufacturing. Additionally, the S5 is compatible with Ultimaker’s Metal Expansion Kit, allowing users to 3D print in stainless steel, expanding its utility for more demanding engineering applications.

6. Seamless Integration with Software and Hardware

The Ultimaker S5 is part of a larger Ultimaker ecosystem, offering seamless integration with Ultimaker Cura, Ultimaker Digital Factory, and the Ultimaker Marketplace. This makes the S5 an excellent choice for those who require networked 3D printing capabilities, remote monitoring, or access to pre-configured material profiles.

The Ultimaker S5’s open filament system allows users to work with a wide range of third-party materials, giving them the flexibility to choose the best material for their specific needs. The Ultimaker Material Alliance also offers pre-optimized profiles for high-performance materials from leading brands, further enhancing the printer’s versatility.

7. Smart Sensors and Calibration

Equipped with smart sensors, the Ultimaker S5 ensures accurate and reliable prints by monitoring various aspects of the print process. For instance, the active bed leveling system ensures that the print surface is perfectly leveled before starting a print, while the filament flow sensors can detect when the material is running low or has jammed, pausing the print to prevent failure.

These smart features reduce the need for manual intervention and ensure consistent print quality, even for complex, long-duration prints. This automation is crucial for professionals who need reliability and precision in their workflow.

8. Pros and Cons of the Ultimaker S5

Pros:

- Versatility with Materials: Can handle a wide range of materials, from polymers to composites and even metals.

- Large Build Volume: Ideal for large prints and multiple-part production.

- Dual Extrusion: Enables complex, multi-material, or multi-color prints.

- Ease of Use: User-friendly software and reliable hardware for a “click and print” experience.

- Integrated Ecosystem: Seamless integration with software and third-party materials.

- Industrial Applications: Suited for advanced engineering and real-world industrial uses.

Cons:

- Higher Cost: The Ultimaker S5 is an investment, with a higher price tag compared to other desktop 3D printers.

- Slower Print Speeds: Dual extrusion and high-quality printing can take longer, especially for complex designs.

- Resin Materials: Limited in material range compared to SLA printers for very fine-detail prints.