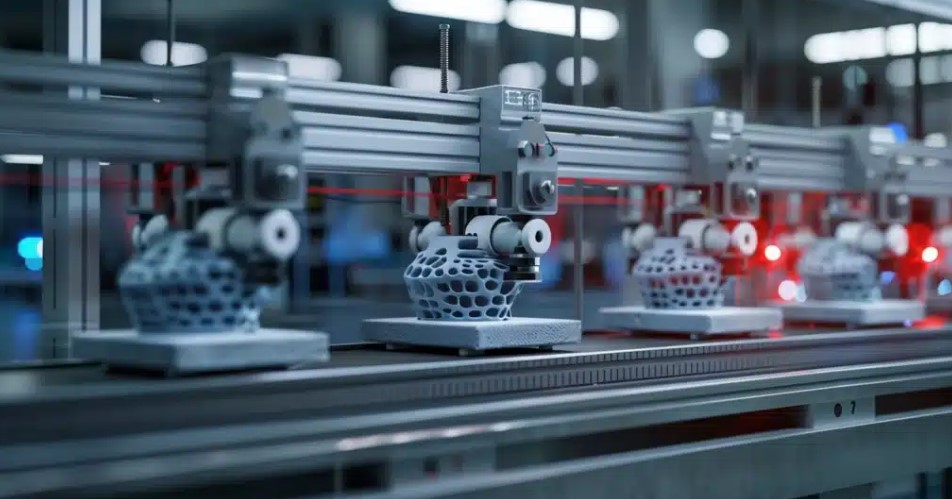

The Role of 3D Printing in Addressing Supply Chain Challenges

1. Simplifying Manufacturing Processes

Traditional manufacturing often involves several stages of production, each requiring different machines, materials, and assembly processes. For complex products, this can mean thousands of individual parts being sourced from multiple suppliers across the globe. 3D printing, on the other hand, enables manufacturers to consolidate components into a single, simplified process. Instead of assembling parts from different regions, companies can print fully functional products in one place, drastically reducing supply chain complexity.

For example, aerospace companies are using 3D printing to consolidate multiple parts of an engine into a single, lightweight component. This simplifies the production process and minimizes the need to transport and assemble various parts from different suppliers, reducing lead times.

2. Localized Production and On-Demand Manufacturing

One of the most transformative aspects of 3D printing is the ability to decentralize production. Rather than relying on a single large-scale manufacturing plant located far from the end market, businesses can establish smaller, localized production hubs equipped with 3D printers. These hubs can produce parts and products on-demand, close to where they are needed.

This shift can have a significant impact on global supply chains by reducing the need for long-distance shipping, cutting down transportation costs, and minimizing lead times. It also makes companies more agile and adaptable, as they can respond quickly to changes in demand without waiting for parts to arrive from overseas.

For example, in the automotive industry, 3D printing allows manufacturers to produce replacement parts on-site, reducing the wait time for repairs and the need for large inventories of spare parts.

3. Reduced Inventory and Warehousing Costs

Traditional supply chains often require companies to maintain large inventories of parts and products to meet demand and avoid shortages. This results in higher warehousing costs and the risk of overstocking, which can lead to waste. With 3D printing, companies can shift to an on-demand production model, where products and parts are manufactured only when needed. This reduces the need for large inventories, cuts down on storage costs, and helps prevent overproduction.

In industries such as healthcare, where specific parts or customized implants are often needed at short notice, 3D printing provides an efficient solution for producing items on demand, without requiring extensive storage facilities.

4. Enhanced Flexibility and Customization

3D printing offers an unprecedented level of design freedom and customization, allowing manufacturers to create products that are tailored to specific customer needs without the limitations of traditional manufacturing. This flexibility can reduce the complexity of the supply chain by enabling companies to produce small batches or even single units without the need for expensive retooling or setup.

For industries like fashion and consumer goods, where demand for personalized products is growing, 3D printing allows for the quick and efficient production of customized items, reducing reliance on mass production and long supply chains.

5. Sustainability and Environmental Impact

One of the major challenges facing global supply chains is the environmental impact of transportation, packaging, and production waste. 3D printing can help address these issues by minimizing material waste and reducing the need for long-distance shipping.

Since 3D printing is an additive process, it builds products layer by layer, using only the necessary amount of material. This contrasts with traditional subtractive manufacturing, where large amounts of raw material are cut away, leading to waste. Additionally, by enabling localized production, 3D printing can significantly reduce the carbon footprint associated with shipping goods across the world.

Impact of 3D Printing on Global Supply Chains

The integration of 3D printing into supply chains is already beginning to have a profound impact on industries worldwide. As the technology advances, its effects on global supply chains are expected to grow:

- Decreased Dependence on Global Suppliers: By enabling localized and on-demand production, 3D printing reduces the need for companies to rely on suppliers from distant regions. This helps mitigate risks associated with supply chain disruptions caused by geopolitical tensions, natural disasters, or pandemics.

- Faster Time-to-Market: With simplified production processes and the ability to produce parts and products on-site, 3D printing can drastically reduce lead times. This allows companies to bring products to market faster, improving their competitiveness and responsiveness to consumer demand.

- Lower Production and Logistics Costs: By reducing the need for transportation, warehousing, and large inventories, 3D printing can help companies save on production and logistics costs. This makes it an attractive option for industries looking to optimize their supply chains.