The Evolution of 3D Printing in Space Exploration

The idea of using 3D printing in space is relatively new but has rapidly gained traction. NASA, ESA (European Space Agency), and private space companies like SpaceX and Blue Origin are actively researching and developing ways to integrate 3D printing into space missions. The key drivers of this evolution are the need for self-sufficiency in space and the reduction of payload costs associated with launching supplies from Earth.

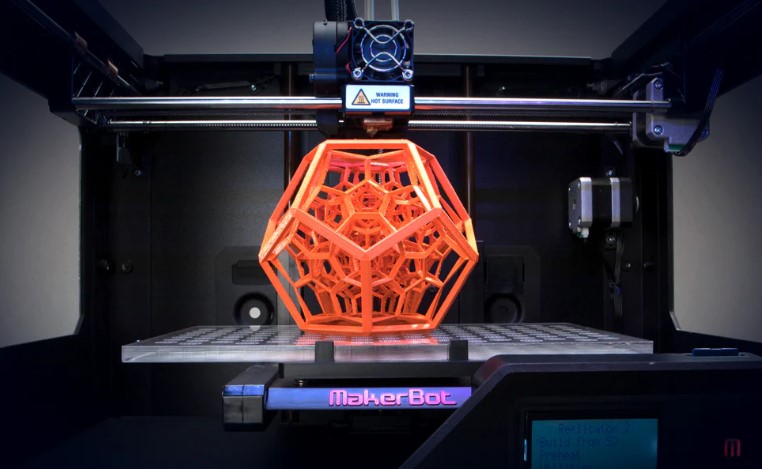

- Early Experiments: In 2014, NASA sent the first 3D printer to the International Space Station (ISS) through the company Made In Space. The initial experiments involved printing simple tools like wrenches, proving that it was possible to produce functional items in a microgravity environment. Since then, 3D printing experiments on the ISS have expanded to more complex components and materials.

- Lunar and Martian Colonization: Looking toward the Moon and Mars, 3D printing could play an integral role in constructing habitats using local materials like lunar regolith (Moon dust) or Martian soil. The European Space Agency, in collaboration with architectural firms, has even proposed 3D printing lunar bases using the Moon’s natural resources.

- Deep Space Missions: For future missions to distant planets, asteroids, or moons, 3D printing could be a critical technology that allows astronauts to be largely self-sufficient, printing tools, replacement parts, and even food during extended missions.

Advantages of 3D Printing in Space Exploration

3D printing offers several advantages in the context of space exploration:

1. Reduced Launch Costs

One of the biggest barriers to space exploration is the cost of launching materials into space. It costs thousands of dollars per kilogram to send supplies on a rocket. By utilizing 3D printing, space missions can reduce the need to carry a large inventory of spare parts and materials, thus minimizing payload weight. Astronauts can print parts and tools as needed, lowering launch costs significantly.

2. On-Demand Manufacturing

In space, unexpected failures of equipment or tools can jeopardize missions. With 3D printing, astronauts have the ability to manufacture tools, spare parts, and other components on-demand. This greatly enhances the flexibility and adaptability of space missions, allowing crews to address issues without waiting for a resupply mission from Earth.

3. Utilization of In-Situ Resources

One of the most promising aspects of 3D printing in space is its potential to utilize local resources. For instance, lunar regolith or Martian soil could be used as raw materials for 3D printing, reducing the need to transport construction materials from Earth. This concept, known as in-situ resource utilization (ISRU), could enable the construction of habitats, landing pads, and other infrastructure directly on the Moon or Mars.

4. Sustainability and Self-Sufficiency

Space missions, especially long-duration ones, require high levels of sustainability. 3D printing can help space missions achieve self-sufficiency by enabling astronauts to repair, recycle, and repurpose materials. Used or broken items could be recycled as raw material for new prints, reducing waste and the need for new supplies.

5. Complex and Custom Designs

Traditional manufacturing methods have limitations in terms of the complexity of parts they can produce. However, 3D printing can create complex geometries and custom designs that are difficult or impossible with traditional methods. This could be critical for space exploration, where lightweight, multifunctional components are necessary to optimize spacecraft and habitat design.

Disadvantages of 3D Printing in Space Exploration

While the benefits are clear, 3D printing in space also has some notable disadvantages:

1. Material Limitations

Current 3D printers are limited in the types of materials they can use. While plastic and metal parts are relatively easy to print, more complex or high-performance materials used in aerospace engineering may not be suitable for 3D printing yet. For example, certain materials required for high-temperature applications or radiation shielding are still difficult to produce using 3D printers.

2. Quality Control

Ensuring the reliability and quality of 3D-printed parts is a challenge, especially in space where failure can be catastrophic. A printed component may not have the same durability, precision, or strength as one manufactured through traditional methods. Quality control measures must be stringent, and the technology needs to improve to guarantee the safety and longevity of 3D-printed parts in critical space missions.

3. Power Consumption

3D printers, especially those capable of working with metals or ceramics, require significant amounts of energy to operate. In space, where power is a precious commodity, the energy requirements for 3D printing could be a limiting factor, especially during long-duration missions with limited energy sources.

4. Slow Printing Times

Compared to traditional manufacturing, 3D printing can be a slow process, especially for large or intricate parts. In emergency situations where time is critical, this can be a significant drawback. Advancements in the speed of 3D printers are needed to make the technology more viable for urgent applications in space.

Challenges of 3D Printing in Space

As with any emerging technology, there are several challenges to overcome before 3D printing becomes a staple of space exploration:

1. Microgravity and Zero Gravity Conditions

3D printing on Earth relies on gravity to help hold materials in place as they are layered. However, in space, microgravity conditions present unique challenges for additive manufacturing. Engineers need to develop specialized printers that can function effectively without the aid of gravity, ensuring that the printed objects maintain their integrity during the process.

2. Limited Availability of Raw Materials

While ISRU offers great potential, the technology to harvest and process extraterrestrial materials like lunar regolith or Martian soil is still in its infancy. More research and development are needed to create effective methods for gathering and preparing these materials for 3D printing.

3. Logistical and Technical Complexities

Setting up 3D printing operations in space is not as simple as sending a printer to the ISS or the Moon. The logistics of maintaining, calibrating, and troubleshooting these printers in space environments are complex. There’s also the challenge of ensuring that the printers are robust enough to withstand the harsh conditions of space.

4. Regulation and Standardization

As 3D printing becomes more integrated into space missions, international space agencies will need to develop standards and regulations to ensure the safety and compatibility of 3D-printed components. Defining these standards and testing 3D-printed parts in space conditions are critical steps that have yet to be fully addressed.

The Future of 3D Printing in Space: What to Expect

The next decade will likely see significant advancements in 3D printing technologies for space exploration. Here are some predictions for how 3D printing will shape the future of space missions:

- Lunar and Martian Habitats: NASA and ESA are actively researching how to 3D print habitats on the Moon and Mars using local materials. This would allow astronauts to live and work in self-sufficient colonies, reducing their reliance on Earth for supplies.

- Long-Duration Space Missions: For missions to Mars and beyond, where resupply from Earth is not feasible, 3D printing will be crucial. Astronauts will likely use 3D printers to create tools, replacement parts, and even food, ensuring the crew can remain autonomous for extended periods.

- Space Manufacturing Facilities: In the future, we may see the development of entire manufacturing facilities in orbit, where materials are mined from asteroids and 3D-printed into useful components. This could open up new possibilities for building space stations, satellites, or even spacecraft entirely in space.

- Space Tourism: As private companies begin offering commercial space tourism, 3D printing could play a role in making these ventures more cost-effective and sustainable. Custom-built habitats and facilities for tourists could be printed in space, reducing the cost and complexity of transporting entire structures from Earth.