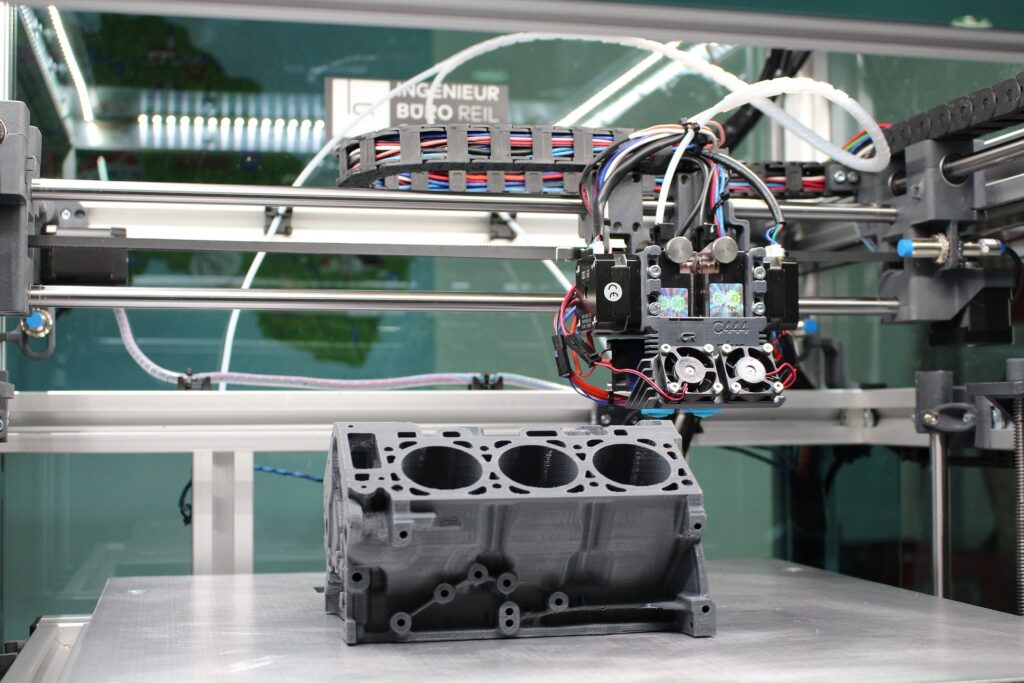

Industrial 3D printing has rapidly evolved, offering unprecedented capabilities in manufacturing, prototyping, and custom production. Choosing the right industrial 3D printer depends on several factors, including material compatibility, build volume, throughput, and the specific needs of your industry.

This blog will dive into some of the best industrial 3D printers for 2024, including resin, SLS, FDM, and composite printers. We will explore the pros and cons of each model and the challenges that may arise when adopting them into your industrial workflow.

1. Resin 3D Printers

Nexa3D XiP Pro

The Nexa3D XiP Pro is a fast and precise industrial resin 3D printer. Known for its speed, this printer offers high throughput for industries that need quick, accurate resin-based prints. It’s widely used in areas like medical devices, automotive, and consumer goods.

Pros:

- Exceptional Speed: The XiP Pro can print faster than many other resin 3D printers, making it a leader in high-throughput production.

- High Detail and Accuracy: Its resin printing technology ensures fine details and a smooth surface finish, suitable for precise applications.

- Versatile Material Use: Compatible with a wide range of resin materials, including engineering-grade resins.

Cons:

- Cost of Resin: Resin can be more expensive compared to other materials, increasing the long-term operational cost.

- Post-Processing: Resin prints typically require additional post-processing steps like washing and curing, which can slow down the overall workflow.

Challenges:

- Handling Resin: Working with resin can be messy and requires specific safety precautions, including proper ventilation and handling procedures.

- Limited Material Durability: Resin parts, while detailed, may lack the toughness of SLS or FDM-printed parts.

Nexa3D NXE 400Pro

The Nexa3D NXE 400Pro is another standout resin 3D printer, designed specifically for industrial and dental applications. It’s perfect for creating high-precision, small parts where accuracy is critical.

Pros:

- Designed for Specialized Applications: Ideal for dental and intricate industrial applications requiring detailed and small-scale parts.

- Large Build Volume: Offers more flexibility for producing multiple parts simultaneously.

- High-Speed Performance: Reduces production times significantly with its fast print speed.

Cons:

- Specialized Materials Required: Often necessitates the use of specialized resins that may not be universally available.

- Higher Price Point: While offering advanced features, it may be cost-prohibitive for smaller businesses or projects.

Challenges:

- Limited Use Cases: While powerful, the NXE 400Pro is geared towards specific applications and may not be as versatile for broader industrial needs.

- Post-Processing: As with most resin printers, post-processing is essential, which can be time-consuming.

2. SLS 3D Printers

Nexa3D QLS820

The Nexa3D QLS820 is a high-throughput Selective Laser Sintering (SLS) 3D printer known for its reliability and scalability. Its robust build volume of 350 x 350 x 400 mm and smart automation features make it a favorite among reputable manufacturers in industries like automotive and aerospace.

Pros:

- High Throughput: Capable of producing large batches of parts quickly, ideal for industrial-scale production.

- Smart Automation: Equipped with advanced automation systems that reduce manual labor and increase operational efficiency.

- Strong, Durable Parts: SLS technology produces highly durable, functional parts without the need for support structures.

Cons:

- High Initial Investment: The QLS820 is a premium machine, and its upfront costs are substantial, which can be a barrier for smaller businesses.

- Powder Handling: SLS requires specialized powder materials, which can be difficult to manage and store.

Challenges:

- Post-Processing Complexity: SLS prints often require additional post-processing like cleaning off powder residue and sometimes additional surface finishing.

- Powder Safety: The powder materials used in SLS can be hazardous if not handled properly, necessitating the need for safety protocols.

3. FDM 3D Printers

Stratasys F900

The Stratasys F900 is a top-tier industrial Fused Deposition Modeling (FDM) printer known for its ability to produce large end-use parts, jigs, fixtures, tooling, and functional prototypes. With its large build volume and robust material compatibility, it’s an ideal choice for industries like aerospace and automotive.

Pros:

- Large Build Volume: With a substantial build volume, the F900 is suitable for large-scale industrial projects.

- High Material Compatibility: Supports a wide range of thermoplastics, including engineering-grade materials like Ultem and PEEK.

- Precision and Reliability: Known for its accuracy in producing large, complex parts that meet rigorous industry standards.

Cons:

- High Cost: The F900 is one of the most expensive FDM printers on the market, making it a significant investment.

- Size and Space Requirements: Its large footprint and need for a dedicated workspace can be challenging for smaller facilities.

Challenges:

- Material Costs: High-performance materials like Ultem and PEEK can be costly, adding to operational expenses.

- Setup and Maintenance: Regular maintenance and calibration are necessary to keep the machine operating at peak efficiency, which can be time-consuming.

4. Industrial Composite 3D Printers

Markforged FX10

Markforged is renowned for its industrial composite 3D printers, and the FX10 is the next generation of their industrial-grade models. It’s perfect for creating strong, lightweight composite parts that are ideal for demanding applications.

Pros:

- Composite Materials: The ability to print with continuous carbon fiber, Kevlar, and fiberglass makes this printer ideal for producing strong, lightweight parts.

- High Precision: Offers excellent accuracy and surface finish, which is crucial for high-performance parts.

- Durability: The parts created by the FX10 are incredibly strong and can withstand tough industrial environments.

Cons:

- Material Costs: Composite materials, particularly continuous fibers, are expensive.

- Slow Build Times: The detailed nature of composite printing means longer print times, especially for large parts.

Challenges:

- Niche Applications: While composite materials are incredibly strong, they are best suited for specific use cases, such as aerospace or automotive components.

- Printer Cost: The FX10, like other Markforged printers, comes at a high price, which may be prohibitive for small-scale operations.

Markforged FX20

The Markforged FX20 is a larger, more robust composite printer designed for producing big, high-strength parts capable of withstanding high temperatures. It’s ideal for aerospace and automotive industries that need durable, functional components.

Pros:

- Large Print Volume: The FX20 offers more space for larger parts compared to the FX10, making it more versatile.

- High-Temperature Capabilities: Capable of producing parts that can withstand extreme temperatures, expanding its range of applications.

- Superior Strength: Thanks to its composite material capabilities, the FX20 produces parts that are both lightweight and incredibly strong.

Cons:

- Premium Price: As a high-end industrial machine, the FX20 demands a significant financial investment.

- Long Print Times: Printing large composite parts with high detail can take considerable time.

Challenges:

- Limited Material Options: While the available materials are excellent, the range is narrower compared to FDM or SLS printers.

- Learning Curve: The FX20’s advanced features may require more in-depth training to fully utilize its capabilities.